Hybrid rubber (or Hybrid Sticky rubber), which increases the speed of sticky rubber by weakening the stickiness of top sheet and combining it with new-generation tension sponge, is rapidly gaining popularity among top players because it is being considered as the solution for the decrease of rotation due to the adaption of poly ball. And the possibility that hybrid rubber becomes the mainstream of table tennis rubber in the future seems to be quite high. Accordingly, many table tennis manufacturers are putting a lot of effort into hybrid rubber and releasing many new products one after another. Donic ‘BlueGrip J’ series newly released in 2025 is also one of those hybrid rubber families.

Donic has been releasing various series of hybrid rubbers since the concept of hybrid rubber was first introduced, and ‘BlueGrip J’ series is the newest hybrid rubber family that will work as the most important hybrid rubber family in Donic rubber range. There have been three families – (1) ‘BlueStar A’ series whose speed can be compared with that of non-sticky tension rubbers, (2) ‘BlueGrip S’ series which adopts softer top sheet for ease of use, and (3) ‘BlueGrip C’ series whose strong stickiness and hard feeling are close to those of Chinese sticky rubbers. Among those three families, ‘Blue Grip J’ has been developed as the mixture of ‘BlueGrip C’ and ‘BlueStar A’. The geometry of top sheet is that of ‘BlueGrip C’ but the rubber formula of top sheet is that of ‘BlueStar A’. Further sponge density has also been adjusted for better ease of use. ‘BlueGrip J’ provides excellent ability of gripping the ball and producing rotation, as a sticky rubber. And, the advantage of ‘BlueGrip J’ is that the players can utilize the ability of producing spin with ease for performing various techniques. Zhang Jike tested the rubbers during development and adjusted detailed specifications. So ‘J’ is the initial of ‘Jike’. The variations in ‘BlueGrip J’ series are distinguished by numbers (= 1, 2, ……), like the other families in Donic rubber range. The sponge densities of ‘BlueGrip J1’, ‘BlueGrip J2’ and ‘Blue Grip J3’ are 55°, 52.5° and 50° respectively (in German Standard). In the standard of Butterfly or DHS, those densities becomes around 42°, around 40° and around 38°.

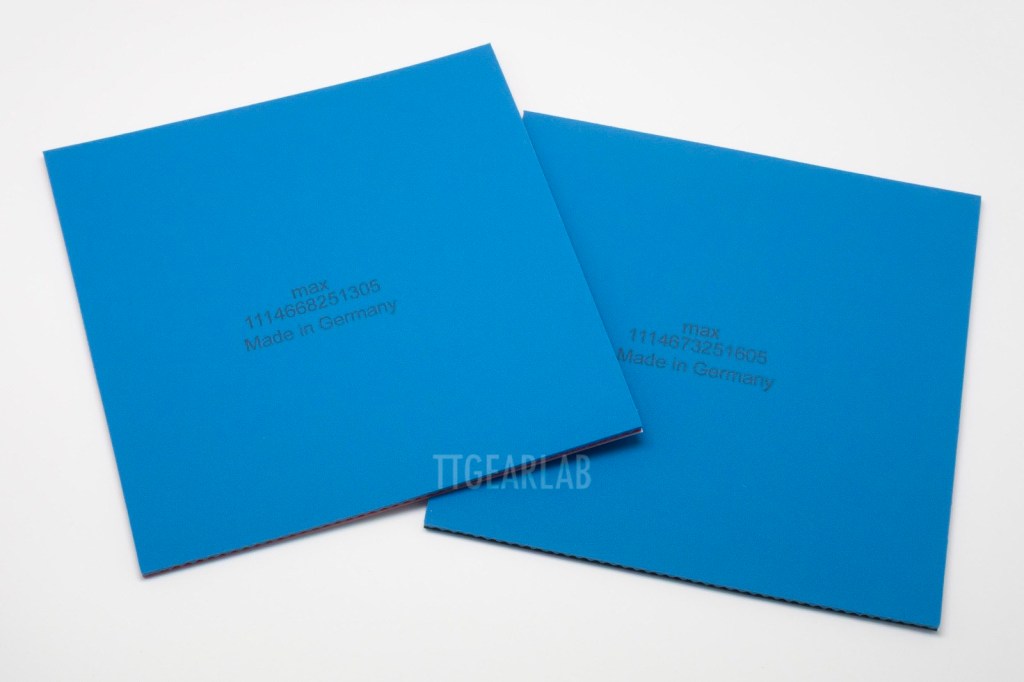

This article shows the pictures of ‘BlueGrip J1’ and ‘BlueGrip J2’.

Donic ‘BlueGrip J’ series consists of three models – ‘BlueGrip J1’ whose (avg.) sponge density is 55° in German standard (= around 42° in Butterfly/DHS standard), ‘BlueGrip J2’ whose (avg.) sponge density is 52.5° in German standard (= around 40° in Butterfly/DHS standard), and ‘BlueGrip J3’ whose (avg.) sponge density is 50° in German standard (= around 38° in Butterfly/DHS standard).

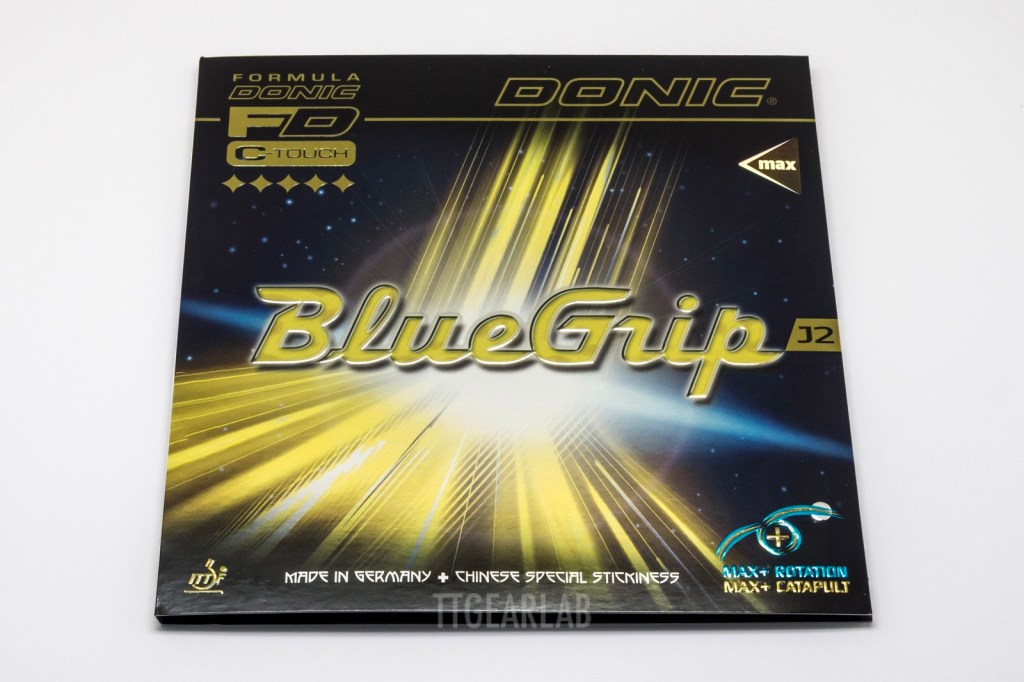

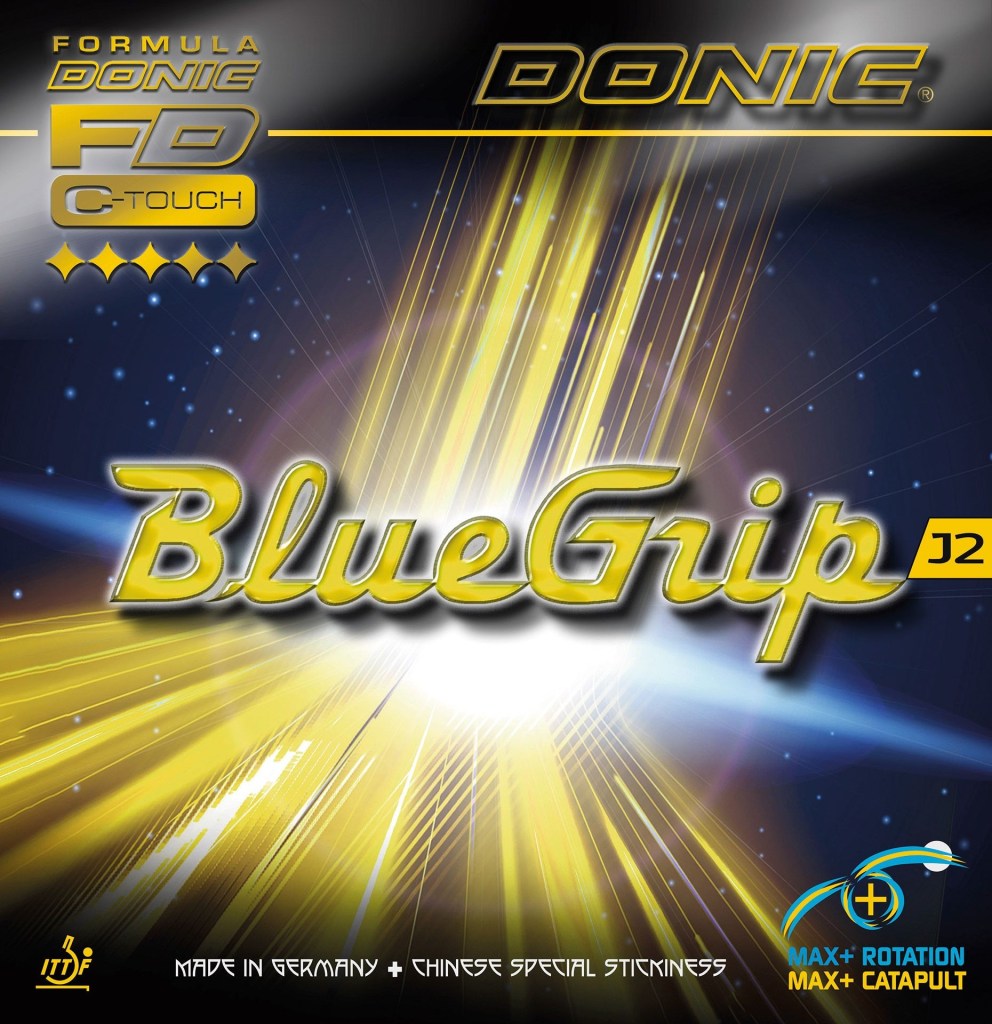

Two rubber technologies – ‘FD (= Formula Donic)’ and ‘C-Touch’ are indicated at the left top of the foreside of packaging. ‘Formula Donic (= FD)’ means that tension effect (= speed glue effect) is integrated in the rubber. The technology name ‘FD’ had been introduced in 1998 with the release of ‘Desto F1’ which is the first tension rubber of Donic. ‘C-Touch’ means that the characteristics of this rubber are close to those of Chinese sticky rubbers, when compared with former sticky rubbers made in Germany. In Donic rubber range, ‘C-Touch’ is applied to two rubber families – ‘BlueGrip C’ and ‘BlueGrip J’. (It seems that ‘C’ is the initial of ‘Chinese’.)

At the bottom of the foreside of packaging, the text ‘Made in Germany + Chinese Special Stickiness’ expresses that ‘BlueGrip J’ is German tension rubber family which is close to Chinese sticky rubbers.

‘BlueGrip J1’ equipped with 55° sponge is the stiffest and the fastest version in the series. Among three models of ‘BlueGrip J’ series, this version is the closest to Chinese sticky rubber in feeling. However, thanks to the softer top sheet with weakened stickiness, it can produce fast ball even in case the player hits the ball directly by large angle.

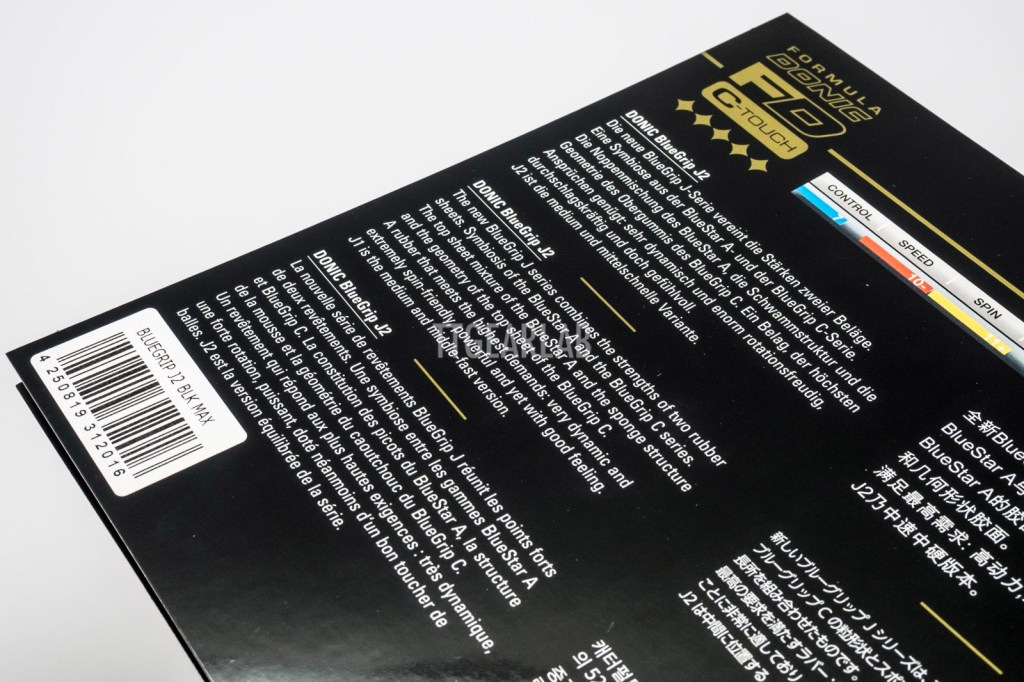

On the back cover of the packaging, the characteristics of the rubber are described in six languages.

‘BlueGrip J2’ equipped with 52.5° sponge is the medium and middle-fast version in the series. It is a bit slower than ‘BlueGrip J1’ but instead it is easier to use. ‘BlueGrip J2’ can be considered as the standard version with best balance in the series.

On the back cover of the packaging, the characteristics of the rubber are described in six languages.

Inside the front cover, it is described that this rubber provides longer lifetime, enhanced catapult effect and improved feeling of tension (= the feeling like speed glue is applied).

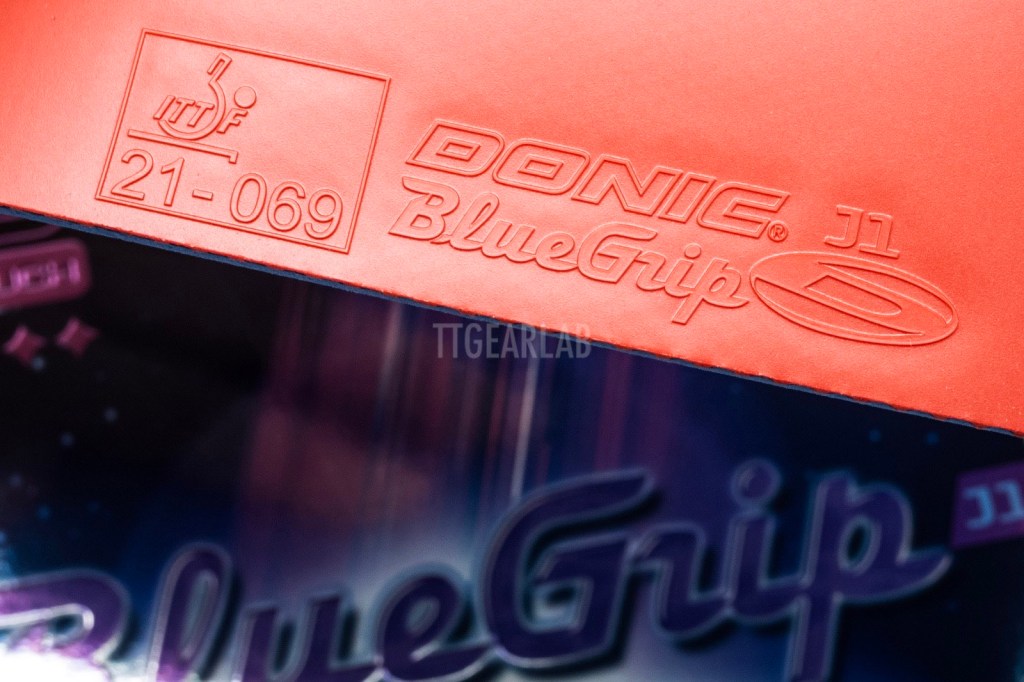

Top sheet is covered by translucent protection sheet which expresses that this rubber is sticky rubbers.

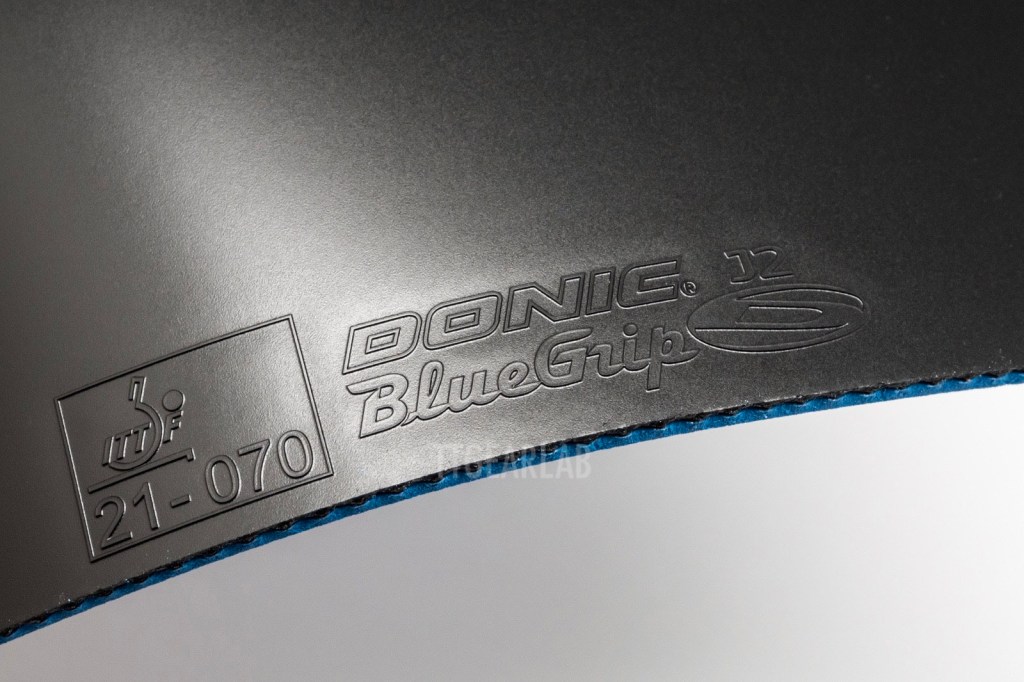

The color of sponge is blue which has been applied for Donic rubbers for long time since the release of ‘BlueFire’ series. Now this blue sponge is considered as the symbol of Donic rubbers.

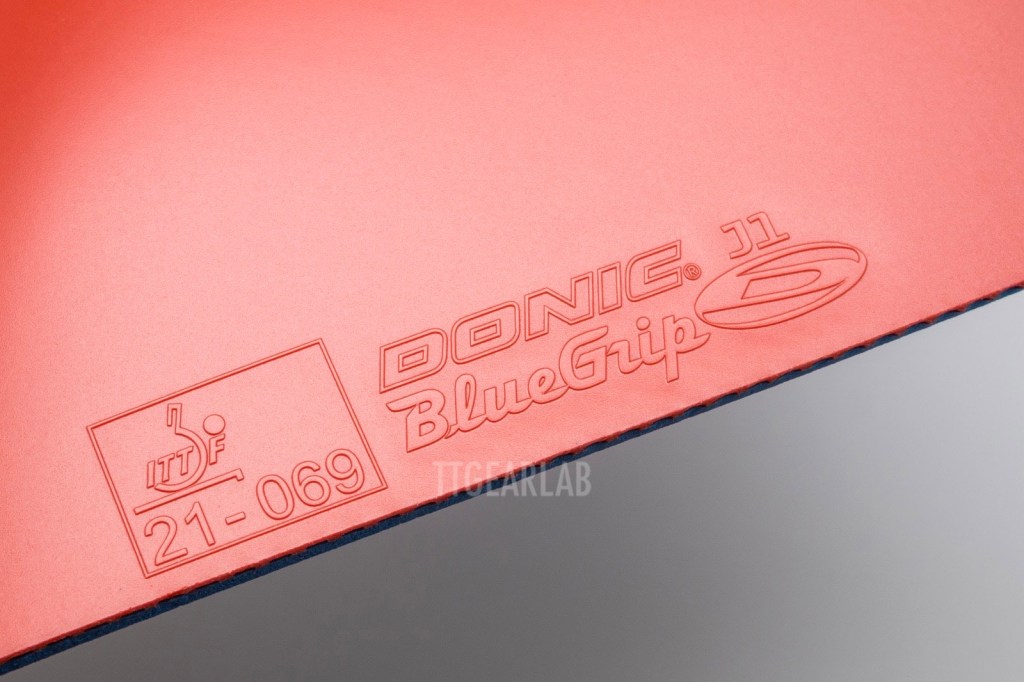

Above picture shows the red top sheet of ‘BlueGrip J1’ and the black top sheet of ‘BlueGrip J2’. ITTF registration numbers are 21-069 and 21-070 respectively.

The feel of the surface of top sheet isn’t visually different from that of non-sticky rubber. In case of Chinese sticky rubbers such as DHS ‘Neo Hurricane 3’, the treatment of the logo area is somewhat different from the body area. But, that kind of difference isn’t seen in recent German sticky rubbers.

The base of top sheet is somewhat thick but not excessively thick. And, the pimple is somewhat low, but not as low as that of ‘Hurricane 3’. So we can expect that the geometry of the top sheet is designed with some speed in mind. Overall structure of top sheet is same as that of ‘BlueGrip C’, but the rubber formula isn’t that of ‘BlueGrip C’ but that of ‘BlueStar A’. The top sheet of ‘BlueGrip J’ combines the shape of ‘BlueGrip C’ and the material of ‘BlueStar A’ to take advantage of both. The sponge is inherited from ‘BlueGrip C’, but density has been lowered for making the balance better.

The average area density (the weight per unit area) of ‘BlueGrip J1’ is around 0.26g/㎠. When combined with a standard size blade, the rubber alone weighs approximately 52 grams.

The average area density of ‘BlueGrip J2’ is around 0.24g/㎠. When combined with a standard size blade, the rubber alone weighs approximately 48 grams.

(Note : About 2 to 4 grams of glue weight will be added here when the rubber is combined with blade. The weight of the glue depends on how the player apply it.)

‘BlueGrip J1’ is recommended for the players who want to play with powerful topspin. Because it is stiff and heavy, it is basically recommended as the rubber for one side (mainly forehand side) of racket.

‘BlueGrip J2’ can be recommended for the players who want to utilize the excellent spin performance for stable rally with various techniques. Because it is lighter and more balanced than ‘BlueGrip J1’, players will be able to use this rubber for both sides of racket without big problem.

TTGearLab will use ‘BlueGrip J’ series for various testing at court.

You can buy Donic BlueGrip J1, BlueGrip J2 and BlueGrip J3 at megaspin.net. If you buy the products through following links, a part of profit is shared by TTGearLab. So it becomes a donation to TTGearLab.

Unauthorized use and/or duplication of this material without express and written permission from this website’s author and/or owner is strictly prohibited. Excerpts and links may be used, provided that full and clear credit is given to TTGearLab with appropriate and specific direction to the original content.

Last week Donic distributor provided many products to TTGearLab. I will be able to write the information of some Donic blades soon.

LikeLike

good news .. i will wait for the article .

LikeLike

I started to add articles on Donic blades. The first one is Anders Lind HexaCarbon and the second is Skachkov Carbon. 🙂

LikeLike

This is helluva new sir, Donic have several budget friendly, but quality blades. Only thing I was missing was to have hard data on them

LikeLike

Thank you for comment. You will be able to find more and more Donic blades on this web site. 🙂

LikeLike

Hey everyone! What are your thoughts on Decathlon’s new Kuikma TTW Progress table tennis blade line? I’m really curious to hear your opinions, they seem super affordable. Decathlon is known for great value, and if these blades offer decent performance for the price, they could be a game-changer for beginners or intermediate players looking to upgrade without breaking the bank.

LikeLike

It is interesting! But, I don’t have any contact with Decathlon. I’ll try to contact them.

LikeLike